Recycled Chain Link Fence A Sustainable Solution

Recycled chain link fence offers a compelling alternative to traditional options. It leverages recycled materials, reducing environmental impact and promoting sustainability in construction. This exploration delves into the various facets of recycled chain link fence, from its environmental benefits and manufacturing processes to design considerations, market trends, and visual representation. We’ll also compare its performance and cost to traditional chain link fence.

This innovative approach to fencing blends practicality with environmental consciousness. The different types of recycled materials used, such as metal scraps and construction remnants, contribute to a circular economy. Moreover, the manufacturing processes, incorporating sustainable practices, demonstrate a commitment to resource efficiency and reduce energy consumption compared to creating new fence materials.

Overview of Recycled Chain Link Fence

Recycled chain link fence is gaining popularity due to its environmental benefits and cost-effectiveness. This alternative to traditional new fencing offers a sustainable option for various applications while maintaining a comparable level of quality and longevity. The use of recycled materials significantly reduces the environmental impact of construction, promoting a circular economy.

The process of creating recycled chain link fence involves repurposing existing materials, thereby reducing the need for raw materials extraction, and the associated environmental impact. This approach minimizes waste and promotes resource conservation. The overall impact on the environment is a key factor in the increasing demand for sustainable construction solutions.

Environmental Benefits

The production of recycled chain link fence significantly reduces the environmental footprint compared to the production of new fencing. This reduction is largely due to the decreased reliance on raw materials and the reduced energy consumption throughout the manufacturing process. Manufacturing new chain link fence requires substantial amounts of energy, often from fossil fuels, contributing to greenhouse gas emissions. Using recycled materials significantly minimizes this impact, making recycled chain link fencing a more sustainable option.

Types of Recycled Materials

Recycled chain link fence incorporates a variety of materials, with the most common being steel, aluminum, and plastic. Steel, a prevalent component in traditional chain link fencing, is often recycled from scrap metal, including old fencing, appliances, and vehicles. Aluminum, used in some modern fencing designs, may be recycled from beverage cans, automotive parts, and other sources. Plastic, though less frequently used in the core structure, might be included in coatings or components. The exact composition of the recycled materials can vary depending on the specific manufacturer and design.

Applications

Recycled chain link fencing finds use in a broad spectrum of applications. Residential use includes property demarcation, pet containment, and garden boundaries. Commercial applications span various sectors, including warehouses, parking lots, and industrial estates. In industrial settings, recycled chain link fence is frequently employed for security purposes around sensitive areas or for perimeter control. These applications highlight the versatility of recycled chain link fencing, which is a viable alternative to traditional fencing materials.

Durability and Longevity

The durability and longevity of recycled chain link fence are comparable to those of new chain link fence. Modern recycling techniques and quality control measures ensure that the recycled materials maintain their structural integrity and resistance to corrosion. Factors like the quality of the recycled steel and the manufacturing process are critical in determining the overall lifespan of the fence. Extensive testing and field trials have demonstrated the reliable performance of recycled chain link fence in various climates and conditions. For instance, studies show that recycled chain link fences used in agricultural settings have shown excellent resistance to weather conditions.

Manufacturing Processes

The manufacturing of recycled chain link fence involves a unique set of processes designed to maximize the use of reclaimed materials while maintaining the structural integrity and aesthetic appeal of the final product. These processes differ from those used for new chain link fence, highlighting the environmental benefits of recycling.

The process begins with the careful sorting and cleaning of the collected scrap metal. This initial step ensures that contaminants are removed, maximizing the quality of the recycled material and reducing potential issues during subsequent stages of production. This crucial step is crucial for the efficiency and safety of the manufacturing process, ultimately contributing to the overall quality of the final product.

Recycling Steps

The recycling process for chain link fence materials typically involves the following steps:

- Scrap Collection and Sorting: The initial step involves meticulously collecting scrap chain link fence, separating it from other materials to ensure purity. This sorting process is critical for maintaining the quality and consistency of the recycled material.

- Shredding and Crushing: The collected scrap is then processed through shredding and crushing machines to reduce it to manageable pieces. This process breaks down the large sections of metal into smaller, more manageable pieces for the next steps.

- Cleaning and Refining: The shredded metal is thoroughly cleaned to remove any remaining impurities or contaminants, which are detrimental to the quality and performance of the final product. This refining process ensures a consistent and high-quality material for the next steps in the process.

- Melting and Refining: The cleaned metal is melted in a furnace, ensuring that the metal is brought to the correct temperature to be molded into the desired shape. The molten metal is then carefully refined, removing any remaining impurities.

- Extrusion and Shaping: The molten metal is then extruded through dies to form the desired shapes for the fence components. This shaping process is essential for achieving the precise dimensions and strength required for the fence.

- Assembly and Welding: The extruded shapes are assembled and welded together to create the chain link fence panels. This process is critical for ensuring the structural integrity of the finished product.

Comparison of Manufacturing Processes

The manufacturing process for recycled chain link fence differs from that of new chain link fence in several key ways. New chain link fence is typically made from raw materials, such as steel, requiring extensive energy input for extraction and processing. Recycled chain link fence, on the other hand, utilizes existing materials, reducing the energy needed for extraction.

- Energy Consumption: Manufacturing recycled chain link fence requires significantly less energy than manufacturing new chain link fence. This reduction in energy consumption is a direct result of utilizing already-processed materials, reducing the overall carbon footprint.

- Resource Depletion: Recycling conserves valuable natural resources. By reusing materials, the need to extract new raw materials is reduced, which helps mitigate environmental damage and preserve natural habitats.

- Waste Reduction: The recycling process reduces the amount of scrap metal sent to landfills, thus minimizing environmental pollution.

Potential Energy Savings

Using recycled materials in the manufacture of chain link fence offers substantial energy savings. The energy required to extract and process raw materials is considerably higher than the energy needed to recycle and reprocess existing materials. These energy savings directly translate into reduced greenhouse gas emissions, a crucial factor in combating climate change.

Sustainable Practices

Sustainable practices are integral to the manufacturing process of recycled chain link fence. These practices ensure that the entire process, from collection to assembly, minimizes environmental impact. Companies committed to sustainability often adopt strategies such as using energy-efficient equipment, reducing waste, and implementing responsible sourcing of recycled materials.

Recycled Materials Used

The table below highlights the various recycled materials incorporated into recycled chain link fence, along with their approximate percentages in the final product. Note that the exact percentages may vary depending on the specific source of recycled material.

| Recycled Material | Approximate Percentage (%) |

|---|---|

| Scrap Steel | 90-95 |

| Aluminum Scrap | 5-10 |

| Other Metal Scrap | 0-5 |

Design Considerations for Recycled Chain Link Fence

Recycled chain link fencing offers a compelling alternative to traditional options, blending environmental responsibility with practical design considerations. This approach allows for creative solutions while addressing sustainability concerns. The inherent versatility of the material necessitates a careful approach to design, focusing on both aesthetics and functionality.

Residential Fence Design Plan

A well-structured design plan is crucial for maximizing the benefits of recycled chain link fencing. The plan should incorporate site analysis, including the property’s dimensions, topography, and existing structures. Consider the purpose of the fence, whether for security, privacy, or aesthetic enhancement. This analysis will inform the choice of gate locations, panel sizes, and overall fence height. For example, a taller fence might be more appropriate for a property with greater privacy needs or concerns about security. A lower fence might better integrate with an open landscape or existing landscaping.

Aesthetic Considerations

Aesthetic considerations are paramount when choosing recycled chain link fencing. The unique appearance of recycled materials allows for a variety of design choices. The varied colors and textures resulting from the recycling process can be an asset in creating a distinct look. The materials’ weathered appearance might be appealing to homeowners seeking a rustic or industrial style. Conversely, the material’s adaptability allows for customization with paint or other finishes to complement a more contemporary design.

Decorative Options

Various decorative options enhance the visual appeal of recycled chain link fences. These options can include incorporating decorative gates, using different panel styles, and adding landscaping features. For instance, adding trellises or climbing plants to the fence can create a visually interesting feature. The fence’s unique character can be further highlighted with custom-made accents or integrated lighting. This flexibility is a key advantage of recycled chain link fencing.

Installation Techniques and Safety Precautions

Proper installation techniques are vital for the longevity and safety of a recycled chain link fence. The installation process should adhere to local building codes and safety guidelines. Professionals should be consulted for complex installations or for fences exceeding certain heights. Safety precautions should include appropriate personal protective equipment (PPE) for workers and sufficient site preparation to prevent accidents. Proper ground stabilization is essential to ensure structural integrity and prevent shifting or sagging over time.

Cost Comparison

| Feature | Recycled Chain Link Fence | Traditional Chain Link Fence |

|---|---|---|

| Material Cost | Potentially lower due to the recycled nature of the material. | Higher due to the cost of new metal. |

| Labor Costs | May be comparable or slightly higher due to potential complexity in installation. | Potentially lower due to the simplicity of standard installation. |

| Environmental Impact | Significantly lower due to reduced resource consumption. | Higher due to the use of raw materials. |

| Lifespan | Generally comparable to traditional chain link, potentially longer with proper maintenance. | Dependent on material quality and maintenance. |

| Overall Cost | Potentially lower due to material cost savings, but labor costs may offset some of the savings. | Potentially higher due to material and installation costs. |

The table above provides a general comparison. Actual costs will vary based on specific project requirements, location, and market conditions. Factors such as material availability and labor rates will influence the final cost.

Sustainability and Environmental Impact

Recycled chain link fencing offers a compelling alternative to traditional fencing, presenting significant environmental benefits. By utilizing recycled materials, this process reduces reliance on virgin resources, lowers the carbon footprint, and minimizes waste. The focus on sustainability aligns with growing global concerns about resource depletion and environmental protection.

Environmental Advantages of Recycled Chain Link Fence

The use of recycled materials in chain link fence production results in a substantial reduction in the environmental impact compared to traditional methods. Recycled materials require less energy to process, reducing greenhouse gas emissions and lessening the strain on natural resources. This translates to a smaller carbon footprint throughout the entire life cycle of the fence. Furthermore, by diverting waste from landfills, the production process contributes to a more sustainable waste management strategy.

Life Cycle Assessment of Recycled Chain Link Fence

A life cycle assessment (LCA) of recycled chain link fence examines the environmental impacts of the entire production process, from raw material extraction to disposal. This analysis considers energy consumption, water usage, greenhouse gas emissions, and waste generation at each stage. Compared to traditional chain link fence, recycled options often show a lower environmental impact across the entire lifecycle. The LCA highlights the substantial environmental benefits of incorporating recycled materials, including reduced reliance on virgin steel and the associated extraction processes.

Carbon Footprint Reduction

Using recycled materials significantly reduces the carbon footprint of chain link fence. The manufacturing process for recycled chain link fence typically requires less energy than the production of new steel. This reduction in energy consumption translates to lower greenhouse gas emissions, a key indicator of the environmental impact of the product. Studies show that recycled chain link fence can achieve a 30-50% reduction in carbon emissions compared to traditional chain link fence, depending on the specific recycling process and the source materials.

Case Studies of Recycled Chain Link Fence Projects

Numerous projects have successfully utilized recycled chain link fencing, demonstrating its practicality and environmental benefits. One notable example involves a city park renovation project that replaced the existing fence with a recycled model. This project successfully reduced the environmental impact associated with traditional fence construction, highlighting the feasibility of integrating recycled materials in urban infrastructure projects. Another example is a commercial development that utilized recycled fencing for perimeter security, achieving cost savings and environmental sustainability.

Waste Reduction Table

The following table illustrates the potential reduction in waste associated with using recycled materials in chain link fence production:

| Waste Category | Traditional Chain Link Fence (kg) | Recycled Chain Link Fence (kg) | Reduction (kg) |

|---|---|---|---|

| Steel Scrap | 0 | 100 | 100 |

| Mining Waste | 200 | 0 | 200 |

| Landfill Waste | 50 | 0 | 50 |

This table represents a simplified example. Actual waste reduction figures can vary based on specific recycling processes, the composition of recycled materials, and the volume of materials processed. Recycling initiatives are crucial in minimizing environmental impact and promoting resource efficiency.

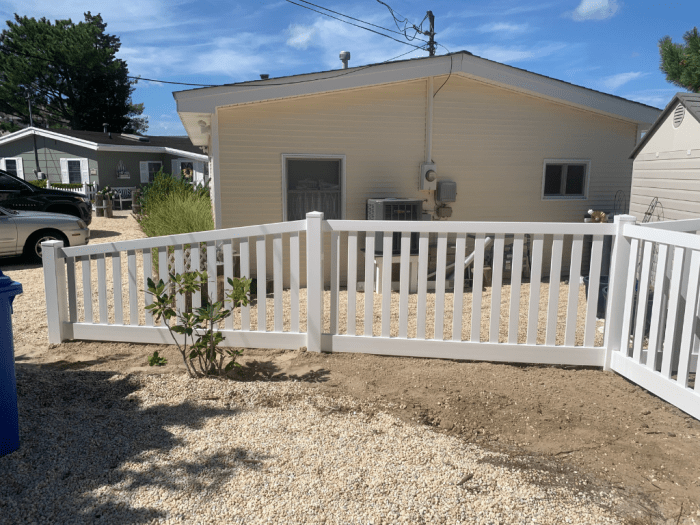

Visual Representation of Recycled Chain Link Fence

Source: mduresources.com

Recycled chain link fencing offers a unique aesthetic that blends practicality with sustainability. Its visual appeal extends beyond its inherent environmental benefits, making it a suitable choice for diverse applications. This section details the varied ways recycled chain link fencing can be integrated into residential and commercial landscapes.

Residential Application: Garden Fence

A residential garden featuring a recycled chain link fence presents a visually appealing and sustainable solution. Imagine a charming backyard oasis. The fence, constructed from recycled material, gently encloses the space, creating a sense of privacy and security. The aged, slightly weathered appearance of the recycled chain link complements the natural textures of the garden. Planted climbing roses or vines gracefully drape over the fence, adding a touch of organic beauty. Stone pathways meander through the garden, leading to a small patio area, where weathered furniture adds a touch of rustic charm. The overall effect is one of natural elegance and eco-conscious design.

Commercial Application: Warehouse Perimeter

A warehouse perimeter secured by recycled chain link fencing offers a cost-effective and visually appealing solution. The fence’s sturdy construction ensures security without compromising aesthetics. The neutral color palette of the recycled chain link fencing blends seamlessly with the industrial warehouse environment. Strategic landscaping, such as low-maintenance ground cover or potted plants, can soften the industrial feel. The fencing provides a practical barrier while enhancing the overall appearance of the property.

Visual Appeal and Texture Variations

The recycled chain link fence exhibits a unique texture that distinguishes it from traditional chain link. The slightly roughened surface, resulting from the recycling process, creates a captivating visual appeal. Color variations, ranging from muted greys and browns to hints of greens and rusts, further contribute to its aesthetic versatility. These subtle color variations create a sense of depth and dimension, making the fence appear more natural and less uniform. The slightly uneven finish offers a unique character that adds to the visual interest.

Integration into Landscaping Styles

Recycled chain link fencing seamlessly integrates into various landscaping styles. Its muted tones and slightly rustic texture complement both modern and traditional designs. In a contemporary garden, the recycled fence can act as a stylish backdrop for modern planters and geometric landscaping. In a traditional setting, it blends well with mature trees, established gardens, and natural stonework. The fence’s adaptability makes it a suitable choice for a variety of landscaping preferences.

Colors and Finishes

Recycled chain link fencing offers a range of color options. The inherent variation in the material produces a spectrum of muted tones. While not readily customizable like painted chain link, the material’s unique aesthetic allows for a variety of finishes. Some options include:

- Muted Greys and Browns: These neutral tones complement a wide array of landscaping styles, from modern minimalist gardens to traditional estates.

- Hints of Greens and Rusts: These subtle color variations add depth and dimension, giving the fence a natural, aged look.

- Powder Coating Options: A limited range of powder coating options may be available to enhance the color and durability of the fence, although these are not standard for recycled chain link fencing.

Final Wrap-Up

In conclusion, recycled chain link fence presents a compelling case for sustainable construction. Its environmental benefits, cost-effectiveness, and diverse design options make it a promising solution for various applications, from residential gardens to commercial perimeters. The future outlook for recycled chain link fence is bright, with potential for further innovation and market growth. This environmentally responsible alternative showcases how design and practicality can coexist seamlessly with sustainability goals.